Machine Vision

Superior quality control in manufacturing

Achieve quality control and automation capabilities with advanced machine vision solutions

Machine vision technology is revolutionizing manufacturing, life science, automotive, agriculture, and more industries through enhanced quality control and automation capabilities. With increasing demands for automation and robots performing complex tasks, machine vision has become crucial for achieving smarter, faster, and more flexible operations.

Product categories within Machine Vision

Custom-built HMIs, Servers, and Cleanroom Tablets for demanding environments. Innovative modular design enables full customization to deliver reliable performance where needed.

Example applications

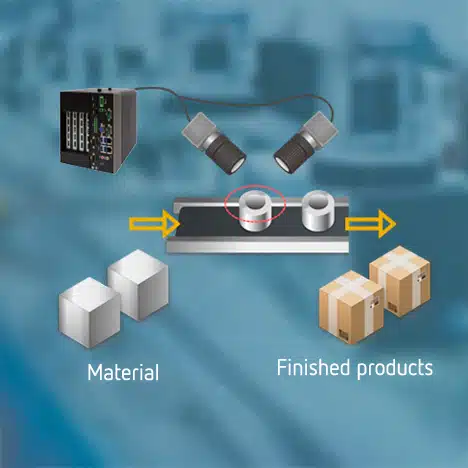

Machine vision technology finds applications across various industries, enhancing quality control and automation. Vision systems excel in inspection of components and materials, automatic sorting, object recognition, and pattern recognition.

The technology serves diverse sectors including automotive, food and beverage, manufacturing, logistics and warehousing, healthcare, energy, and agriculture. Systems can be configured with either powerful CPUs for standard processing tasks or GPU acceleration for advanced applications requiring intensive image processing capabilities.

Partnering with Blue Line

Only the best technology partners

IT hardware for Machine Vision

For more than 35 years Blue Line has provided IT hardware for demanding environments internationally. From standard products to customer-specific solutions, created in close cooperation with our customers.

Need help with your specific solution?

Don’t hesitate to reach out by phone, e-mail, or the form below.

Looking for someone special? Find our employees here