Automation

Reliably designed IT for Automation

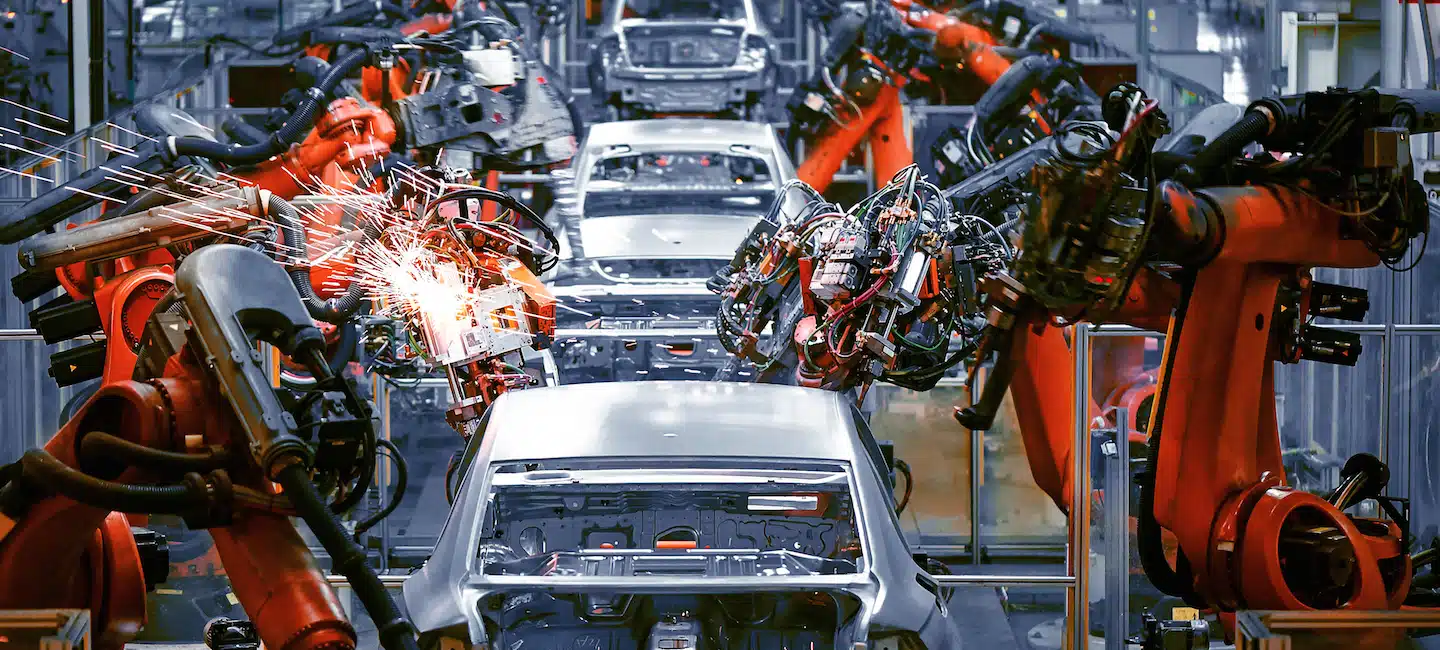

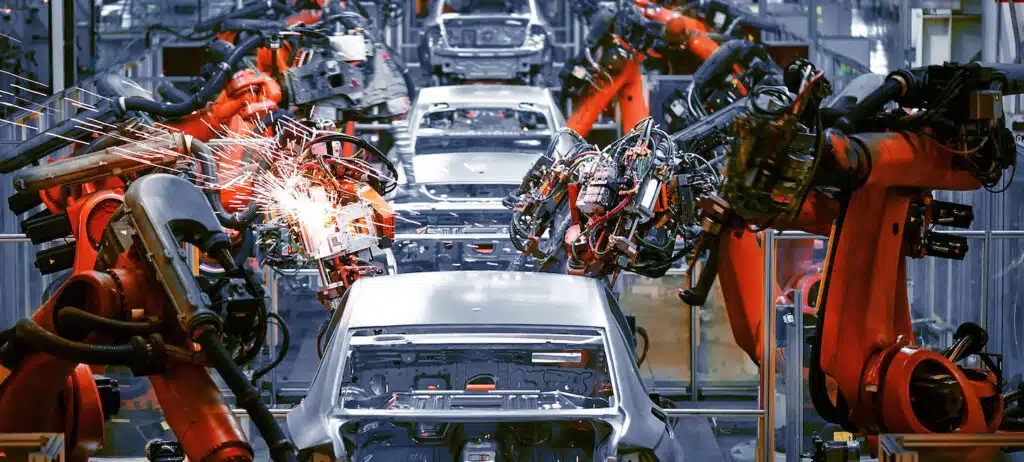

Manufacturing and optimizing with reliable automation solutions

Modern manufacturing demands robust, reliable hardware solutions that can keep pace with increasingly complex automation requirements. When operational efficiency and system reliability are paramount, choosing the right automation hardware becomes a critical success factor.

Industrial automation solution ensures reliable passenger communication

View case study“Blue Line helped develop a new version of the audio controller. We needed to ensure all Banedanmark’s requirements were met, particularly the critical 24/7/365 operation. Blue Line’s dedicated service and support department gives us confidence that the solution is right and operating optimally.”

Morten Wesenberg, Project Manager, Banedanmark

Product categories within Automation

Custom-built HMIs, Servers, and Cleanroom Tablets for demanding environments. Innovative modular design enables full customization to deliver reliable performance where needed.

Example applications

Industrial automation systems benefit from both embedded computers and robust box computers designed for specific applications. These solutions excel in robotics, transportation, agriculture, and manufacturing settings.

For specialized needs, high-performance GPU computing enables advanced capabilities like machine learning and real-time process optimization, driving the future of smart manufacturing.

Whether your system requires high performance GPUs or standard CPU based systems, Blue Line’s industrial computers are configurable with the processor power, storage, connectivity, and I/O needed for your application, like CAN, Ethercat, DeviceNet and serial.

Partnering with Blue Line

Serving world-leading clients and institutions

IT hardware for automation

For more than 35 years Blue Line has provided IT hardware for demanding environments internationally. From standard products to customer-specific solutions, created in close cooperation with our customers.

Only the best technology partners

Need help with your specific solution?

Don’t hesitate to reach out by phone, e-mail, or the form below.

Looking for someone special? Find our employees here